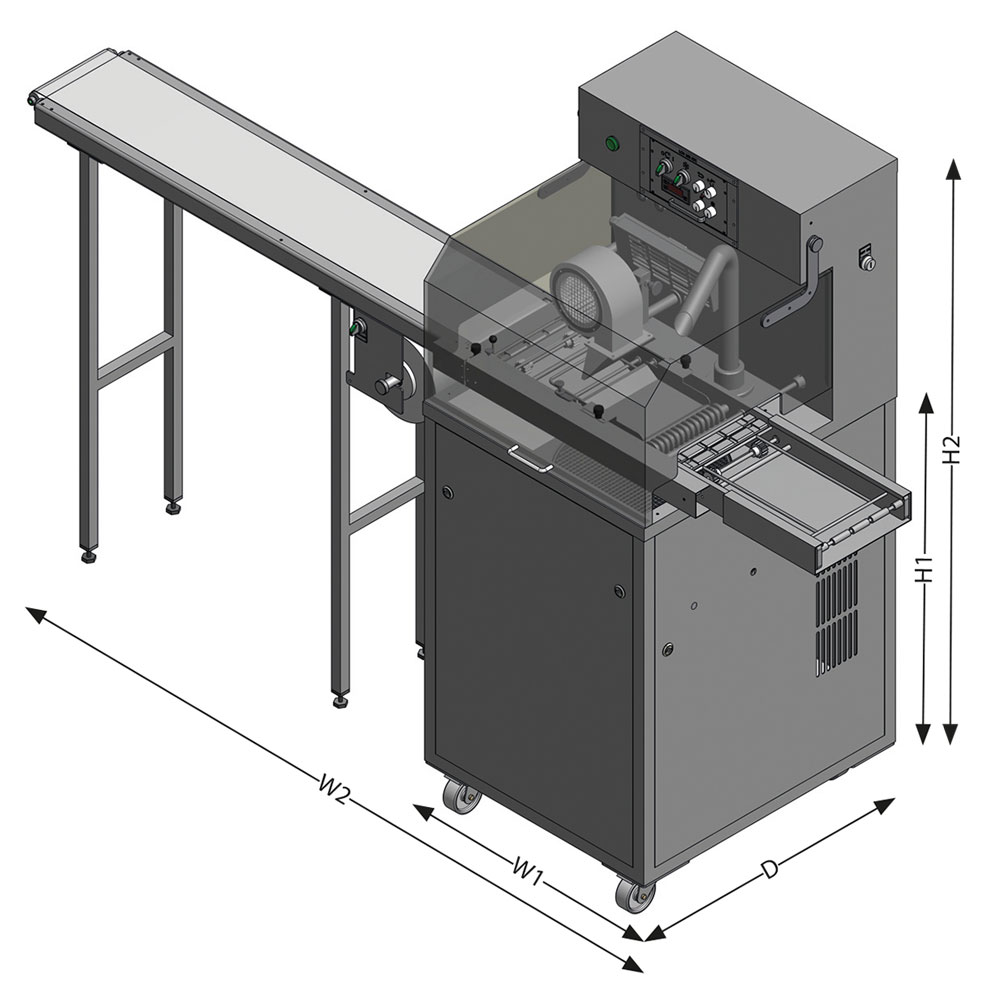

Enrobers

Enrobers is designed to coat many products Apply chocolate or caramel to your product. , designed and constructed on the basis of many years of experience in confectionery. Chocolate, blends or caramels are applied precisely and consistently to the basis of the confectionery product. Customers need easy-to-clean devices that guarantee accurate weight management of applied coatings, easy machine maintenance, low downtime. All this has been achieved through the construction of this device.

enrobing with real chocolate or compound, external tempering.

Individual belongings for enrobing systems can be delivered, e.g. handling of chocolate, feeding-systems, decoration systems, conveyors and curves etc.

Capacity Range: Widths of 200,400,500,600,800and1200 MM

Capacities depend on product, coating layer thickness, type of coating material and required cooling times.

| Features | Benefits |

| Cantylever design |

|

| All stainless steel execution with FDA approved materials |

|

| Detachable lower tank and conveyor |

|

| Built-in control panel |

|

| Electrically titable mesh table |

|

| Use of linear and rotational actuators |

|

We’d love to discuss your business’ equipment requirements. Please submit your enquiry below and we’ll get in touch soon. All fields indicated with a red asterisk are mandatory.