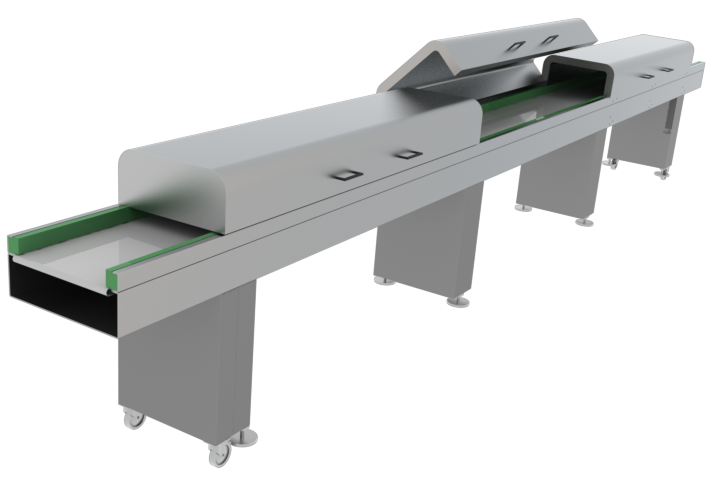

Cool tunnels

Cooling tunnels have a bandwidth of 300mm. up to 1500mm. and are equipped as standard with an input table, a cooling section of 6, 8 or 10m. and take-off table with release piece. The drive of the tunnel was built under the take-off table.

The belt speed is adjustable from 0.6 to 1.8m / min. The belt is controlled by two pneumatic belt controls controlled by photocell, one at the front and one at the rear of the tunnel.

The conveyor belt is of the single-layer type . At the end (in the drive station) a scraper blade is provided with a tray for the chocolate chips underneath. Both the entrance and exit sides are provided with a knife transition. The return conveyor runs back into the refrigerated space, which means that no extra energy is needed to cool the heated conveyor belt back. The tire tread is a polished stainless steel plate, These stainless steel plates are easy to disassemble so that the tunnel can be cleaned easily.

The cooling part is equipped with insulated hinged cover caps, each with a length of 1000mm.,.

The hermetically air-cooled cooling group and evaporators are fitted as standard at the bottom of the cooling tunnel. The evaporator is made of copper and equipped with centrifugal fans with a low noise level. The coolant used is R404A.

The temperature is controlled by a PID controller, which has a double readout where both the requested and the actual temperature can be read.

The cooling tunnel is supplied as standard with convection cooling, but these are also available with convection and / or radiation cooling.

Depending on the product, other types of tires are also available, such as steel straps, special rubber tires, modular link belts … If you wish, please provide a detailed product description of the medium to be cooled.

| Application |

| Cooling of chcolate or compound enrobed product |

| Capacity range |

| The capacity is determined by the length of the Cooling Tunnel |

| Features | Benefits |

| PVC laminated Stainless steel cladding |

|

| PU isolation |

|

| Convection or Radiation cooling |

|

| Auto-centering belt system |

|

| Independent belt and mesh speed variation |

|

| PLC plus LCD |

|

We’d love to discuss your business’ equipment requirements. Please submit your enquiry below and we’ll get in touch soon. All fields indicated with a red asterisk are mandatory.